Introduction to Heavy-Duty Hinges

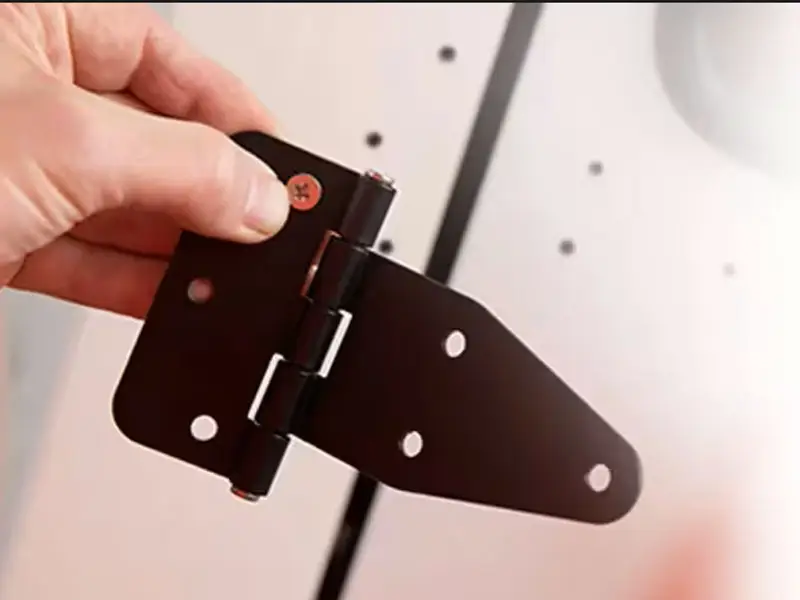

Heavy-duty hinges play a crucial role in various applications where enhanced strength and durability are required. Unlike standard hinges, which are suitable for light to moderate weight doors or cabinets, heavy-duty hinges are specifically designed to support significant loads. These robust components are essential in areas such as construction, automotive manufacturing, and industrial equipment, where the stresses and strains on structural elements can be extreme.

The primary purpose of heavy-duty hinges is to provide reliable rotation or support for objects that necessitate both stability and movement under substantial weight. For instance, in the construction industry, heavy-duty hinges are often utilized for large gates, access doors, and industrial cabinets, ensuring that these fixtures can withstand rigorous use without compromising their mechanical integrity. Their applications extend to commercial settings as well, where equipment and furniture must endure the rigors of everyday usage.

When distinguishing between standard and heavy-duty hinges, one must consider several factors, including load capacity, material composition, and design features. Heavy-duty hinges are typically made from stronger materials such as stainless steel or reinforced metals, which enhance their ability to withstand heavy weights and resist wear over time. Additionally, these hinges often feature advanced designs that promote smooth operation under pressure, reducing the likelihood of mechanical failure.

Load capacity is a critical factor when selecting heavy-duty hinges. It is imperative to assess not only the actual weight of the door or gate but also the dynamic forces that may be exerted during use. Choosing the right heavy-duty hinge, tailored to specific application requirements, is essential for ensuring long-term performance and reliability, ultimately impacting overall maintenance and operational efficiency.

Factors Influencing Load Capacity

When evaluating the load capacity of heavy-duty hinges, several critical factors must be considered to ensure proper functionality and durability. Primarily, the materials used in the construction of the hinge play a significant role. Common materials include stainless steel and brass, each offering distinct advantages. Stainless steel, for instance, is renowned for its strength and resistance to corrosion, making it suitable for environments that may expose the hinge to moisture or chemicals. Brass, while also sturdy, provides aesthetic appeal and is often chosen for decorative applications where appearance is a priority. The choice of material directly impacts the hinge’s ability to support substantial weight over time.

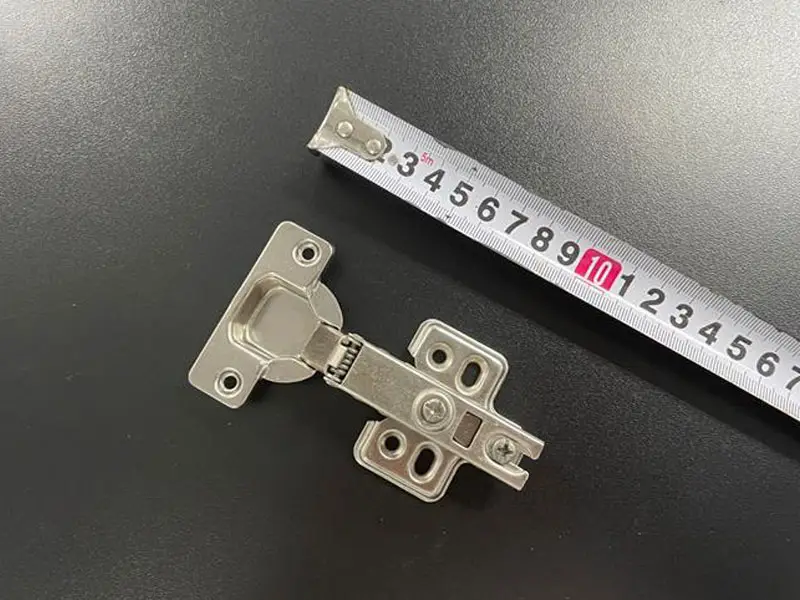

Additionally, the design features of the hinge significantly affect its load capacity. A hinge with multiple knuckles is generally more robust, as it distributes weight more effectively compared to those with fewer knuckles. The size of the hinge pin is another pivotal factor; a larger diameter pin can typically withstand greater loads due to increased strength. Furthermore, the overall surface area of the hinge contributes to its ability to bear weight, with larger surface areas providing better distribution of forces when the hinge is under load. Each of these features must be carefully considered to achieve the desired performance.

Manufacturing standards and specifications also play a critical role in determining hinge load capacity. High-quality manufacturing processes, adherence to recognized industry standards, and certifications ensure that hinges are capable of withstanding defined loads without failure. Choosing hinges that meet these standards not only assures reliability but also enhances safety in applications where heavy loads are a concern. By understanding these factors, users can make informed decisions and select hinges that align with their specific needs and requirements.

Determining the Right Load Capacity for Your Application

When selecting heavy-duty hinges for your application, determining the appropriate load capacity is crucial. To begin, one must calculate the total weight that the hinge will need to support. This involves both the static and dynamic loads, as these two factors have distinct implications for hinge performance. Static loads refer to a constant weight, while dynamic loads involve moving parts or fluctuating weight distributions that can significantly affect the loading conditions on the hinge.

To calculate the total weight supported by the hinge, start by assessing the weight of the door or the equipment being mounted. Additionally, consider any additional forces that might act on the hinge during operation, such as wind load or vibrations. For instance, in a door application, the weight of the door itself may be complemented by factors like the wind pressure, which can increase the load on external hinges. The combined weight will guide you in selecting a hinge with an appropriate load capacity.

Another important aspect to consider is the safety margin. It is generally recommended to choose a hinge with a load capacity that exceeds the calculated requirement to account for unforeseen circumstances. A safety factor of at least 1.5 to 2 times the expected load can avert potential hinge failures. This extra capacity provides a buffer, ensuring that the hinge can handle unexpected surges in weight or stress.

Case studies illustrate these principles in action. For example, in industrial settings where heavy gates are frequently used, hinge specifications must reflect not only the weight of the gates but also the operational conditions they face. Ultimately, understanding the specific needs of your application will facilitate informed decisions regarding hinge load capacity, ensuring durability and reliability.

Conclusion and Recommendations

In summary, understanding load capacity is pivotal when selecting a heavy-duty hinge. The hinge is an essential component that affects not only the functionality of a door or gate but also the overall safety and reliability of the installation. Throughout this discussion, we have highlighted the critical factors that determine the appropriate load capacity for a heavy-duty hinge, including the material, size, and design specifications. Each of these elements provides insights into how a hinge will perform under various conditions.

As you proceed with your hinge selection, it is advisable to consult the specifications provided by manufacturers to ensure you are choosing a hinge that meets your specific needs. Pay close attention to load ratings, as these numbers will guide you in purchasing the right hinge that can withstand the expected weight. Additionally, it may be beneficial to seek expert advice, especially for unique applications. Professionals can offer valuable insight into choosing a heavy-duty hinge that aligns with both safety requirements and performance expectations.

Moreover, considering the longevity and maintenance of the hinge is essential. Selecting a hinge made from durable materials will not only extend its lifespan but also minimize maintenance efforts over time. Regular inspections and proper lubrication can significantly enhance the hinge’s performance and reliability. Finally, we invite you to reach out for further information regarding heavy-duty hinges or to share your experiences in using them. Engagement with others can provide additional perspectives and best practices that may enhance your understanding and application of load capacity in hinges.