Understanding Steel Hinges: Types and Applications

Steel hinges are essential components widely used in various applications, playing a critical role in ensuring functionality and durability. The types of steel hinges vary significantly, including butt hinges, continuous hinges, and concealed hinges. Each type serves distinct purposes and is suited for different environments, thus highlighting the necessity of selecting the appropriate hinge for specific applications.

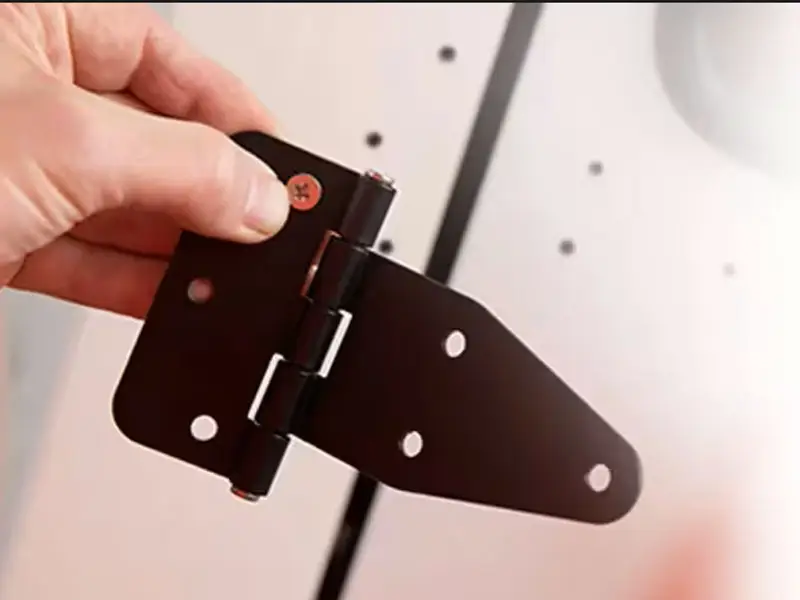

Butt hinges are among the most common types used primarily in residential and commercial doors. They consist of two plates, or leaves, that are joined together by a pin, allowing for a swinging motion. Their robust design accommodates heavy doors, making them popular in both construction and furniture manufacturing. Continuous hinges, also known as piano hinges, extend the entire length of the door, providing even weight distribution that enhances stability and longevity. These hinges are often found in industrial equipment and large enclosures, where consistent performance is critical under heavy usage.

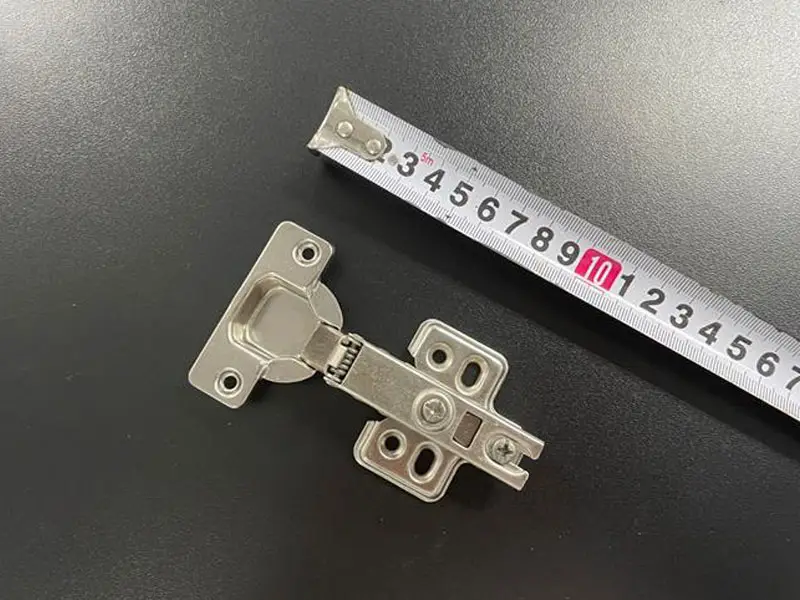

Concealed hinges are designed for applications requiring a sleek and unobtrusive look. These hinges are hidden from view when the door or panel is closed, making them particularly favored in modern furniture design and cabinetry. They offer a blend of functionality and aesthetic appeal, ensuring that the focus remains on the overall design rather than the hardware. The quality of steel used in all these hinge types is paramount; high-quality steel ensures resistance to wear, corrosion, and fatigue, directly affecting performance and lifespan.

In more demanding scenarios, such as in marine applications or environments prone to moisture, hinges made from stainless steel or specially treated steel can significantly enhance durability. Thus, understanding the various types of steel hinges and their applications is crucial for selecting the right products. By choosing high-quality steel hinges tailored to the specific needs of each application, manufacturers can achieve optimal performance and reliability in their projects.

The Benefits of High-Quality Steel in Hinge Manufacturing

The use of high-quality steel in hinge manufacturing plays a critical role in determining the overall performance and reliability of hinges. One of the primary advantages of utilizing superior-grade steel is its exceptional durability. High-quality steel exhibits remarkable strength, allowing hinges to withstand significant mechanical stress and heavy loads. This is particularly important in applications such as industrial machinery and heavy doors, where hinges must operate smoothly without compromising structural integrity.

In addition to durability, high-quality steel offers impressive corrosion resistance. Hinges are frequently exposed to various environmental conditions, including moisture, temperature fluctuations, and corrosive substances. Using steel that is specifically engineered to resist corrosion can significantly extend the lifespan of hinges, reducing the risk of rust and deterioration. This characteristic not only enhances reliability but also lowers the long-term maintenance costs associated with hinge replacement and repairs.

Moreover, the ability of high-quality steel to support heavy loads without deformation ensures that hinges maintain their functionality over time. Manufacturers benefit from this attribute, as long-lasting products contribute to customer satisfaction and trust. Additionally, end-users experience convenience, as the need for frequent maintenance is diminished, further highlighting the advantages of incorporating high-quality steel in hinge production.

Ultimately, the strategic choice of high-quality steel in hinge manufacturing provides substantial benefits across various domains. These advantages include improved durability, enhanced corrosion resistance, and capacity to bear heavy loads. By investing in superior-grade steel, manufacturers not only create reliable products but also contribute to a more sustainable and cost-effective industry. This commitment to quality ultimately benefits both manufacturers and end-users, fostering a cycle of trust and satisfaction.

Quality Control in Steel Sourcing and Production Processes

Quality control is a critical aspect of the manufacturing of steel hinges, ensuring that the raw materials used are of superior quality while adhering to industry standards. The integrity of steel hinges relies heavily on the quality of the steel sourced, and therefore manufacturers must emphasize stringent quality control measures during the sourcing and production processes. High-quality steel should meet specific standards such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization), which outline the necessary specifications for strength, durability, and corrosion resistance.

When selecting steel suppliers, manufacturers should look for certifications that demonstrate adherence to these standards. These certifications not only assure quality but also provide transparency regarding the material properties of the steel. Additionally, implementing a robust quality assurance program throughout the production process is vital. This includes regular inspections and testing of the raw materials, as well as frequent evaluations of production lines to ensure that manufacturing practices maintain the desired specifications.

It is crucial for manufacturers to be aware of the potential pitfalls of using subpar steel. The consequences of using low-quality materials can be significant, leading to product failures, increased liability, and serious safety issues. Hinges made from inferior steel may exhibit problems such as rusting, bending, or even breaking under stress, which can compromise their functionality and pose risks in safety-sensitive applications. Hence, by integrating comprehensive quality control measures during both the sourcing of raw steel and the manufacturing processes, manufacturers can mitigate risks and ensure the production of reliable and high-performing steel hinges.

Future Trends in Steel Hinges and Material Innovations

The manufacturing landscape for steel hinges is undergoing significant transformation, driven by advancements in materials science and technology. As industries seek to improve performance and sustainability, the development of high-quality steel and innovative alloys has become imperative. Emerging trends indicate a shift towards the use of advanced steel alloys that offer superior strength-to-weight ratios, enhanced durability, and increased resistance to environmental factors. These innovations not only improve the functionality of steel hinges but also align with growing demands for environmentally friendly manufacturing practices.

One of the core trends in steel hinge manufacturing is the integration of smart technology. Smart hinges equipped with sensors can provide real-time performance data, facilitating proactive maintenance and increasing the lifespan of products. This technological infusion allows manufacturers to enhance efficiency and optimize production processes while minimizing waste. Additionally, incorporating technology into hinge systems can lead to better user experiences through features such as automatic locking mechanisms, contributing to enhanced security and convenience.

Moreover, the evolution of lightweight but robust materials presents exciting possibilities for the future of steel hinges. Innovations such as composite materials and advanced polymer blends are gaining traction, enabling manufacturers to produce hinges that maintain strength while reducing overall weight. This aspect is particularly crucial in automotive and aerospace applications, where weight reduction can lead to substantial improvements in fuel efficiency and overall performance. As research continues, the potential for new metal alloys and hybrid composites will likely redefine hinge design standards across various sectors.

As these trends evolve, it is evident that the future of steel hinges will be characterized by a commitment to performance, sustainability, and technological advancement. The integration of innovative materials and smart features is set to elevate the quality and reliability of steel hinges, ensuring they meet the demands of contemporary applications while paving the way for new industrial possibilities.