Understanding Hinges: Basics and Functionality

Hinges are fundamental mechanical devices that facilitate the movement of objects, primarily allowing for rotation along an axis. They play an essential role in various applications, such as doors, gates, and furniture, enabling these structures to open and close seamlessly. By serving as a pivot point, hinges allow for efficient access to enclosed spaces, enhancing both functionality and user convenience.

The primary function of a hinge is to connect two components while permitting angular movement, thus enabling operations such as opening, closing, and folding. In construction and cabinetry, hinges ensure that doors can swing freely, which is essential for usability. Without hinges, doors would be inoperative, leading to potential barriers in both residential and commercial settings. Additionally, hinges support a variety of weights and sizes, from lightweight cabinet doors to heavy security gates, thereby contributing to operational efficiency across different contexts.

An important aspect of hinge design is its influence on durability and longevity. The material used, the type of hinge mechanism, and the way it is installed can significantly impact its performance. For example, stainless steel and brass are commonly used materials that resist rust and wear, ensuring that hinges can withstand the stresses of frequent use. Moreover, different types of hinges, such as piano hinges, butt hinges, and concealed hinges, offer varied functionalities tailored to specific needs. Choosing the right hinge type and material can significantly enhance the lifespan and reliability of the installation.

Overall, understanding hinges and their functionality is imperative for anyone involved in construction or furniture design, as these devices are crucial to creating durable, accessible, and efficient structures. The proper selection and installation of hinges can lead to improved user experience and long-term satisfaction.

Common Types of Hinges: An In-Depth Look

Hinges are essential hardware components that facilitate the opening and closing of doors, gates, and various types of panels. Among the numerous types of hinges available, some stand out for their specific characteristics and applications. This section will detail the most common types of hinges, including butt hinges, continuous hinges, piano hinges, and others, highlighting their unique features and typical uses.

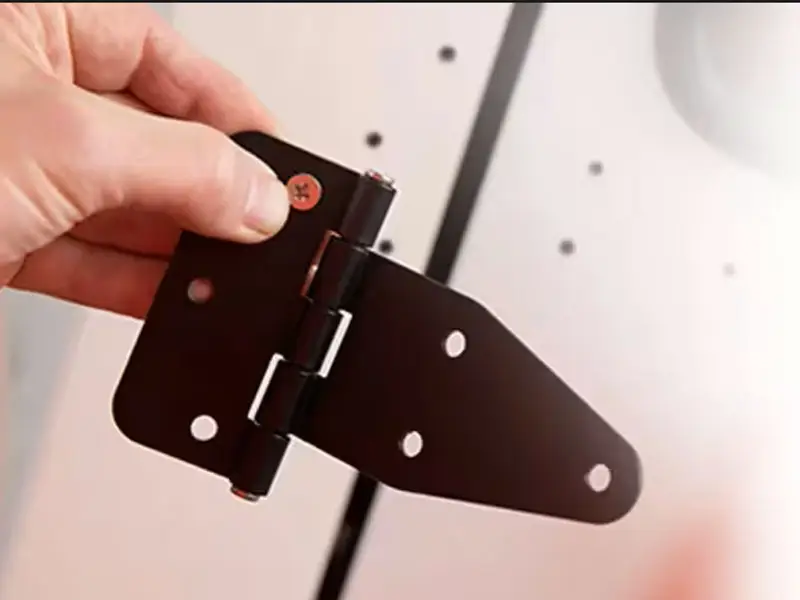

Butt hinges are perhaps the most widely recognized hinge type. They consist of two plates, known as leaves, that are attached to the door and the frame. This hinge type allows for 180-degree motion, making it ideal for residential and commercial doors. The primary advantage of butt hinges is their durability; they can handle heavy loads and frequent use, making them a reliable choice among builders.

Another type to consider is the continuous hinge, also known as a piano hinge due to its extensive use in piano construction. This hinge type runs the entire length of the door or panel, distributing weight evenly and providing excellent support. Continuous hinges are versatile and can be used in various applications, from cabinetry to machinery access points. Their design also minimizes the risk of sagging over time.

Piano hinges have a similar function to continuous hinges but are typically narrower. They are particularly valuable in situations where space is limited, such as in foldable furniture or compact machinery. Their design allows for a smooth, flush fit and uninterrupted motion, making them ideal for portable applications.

Lastly, spring hinges are equipped with a built-in spring mechanism that automatically returns the door to a closed position after being opened. These hinges are commonly used in commercial settings where self-closing functionality is essential, such as in fire doors or restroom facilities.

By understanding the various common types of hinges and their applications, one can make informed decisions for specific projects, ensuring optimal functionality and longevity.

Specialized Hinges: When Standard Just Won’t Do

In the realm of hinge design, specialized hinges serve essential functions that extend beyond those offered by standard models. These hinges have been engineered to meet unique requirements across diverse applications, ensuring optimal performance and visual appeal. Three notable examples of specialized hinges are concealed hinges, hidden hinges, and spring-loaded hinges, each serving specific needs in architectural and functional design.

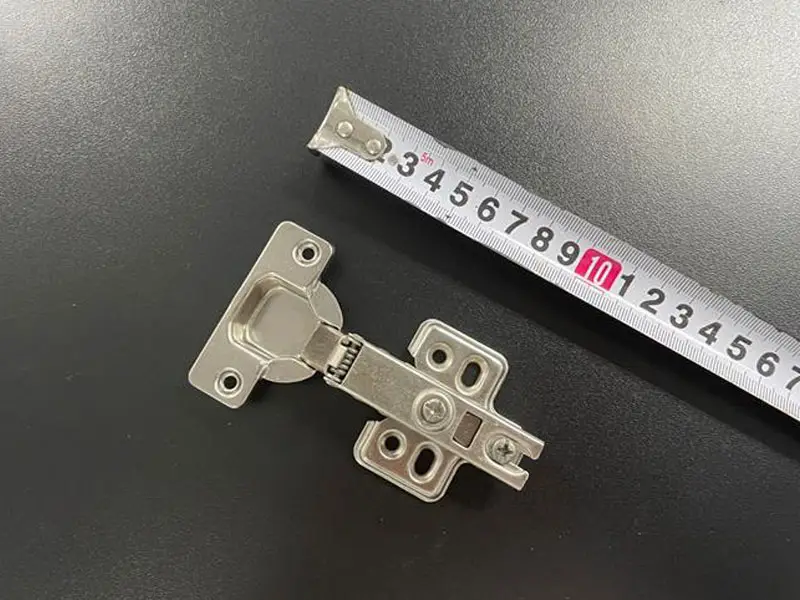

Concealed hinges, as the name suggests, are designed to remain hidden when the door is closed. They operate within the thickness of the door and frame, providing a seamless appearance that is particularly desirable in modern design contexts. These hinges are ideal for applications where aesthetic integrity is paramount, such as in cabinetry or high-end residential projects. Aside from aesthetic considerations, concealed hinges often contribute to smoother door operation and added security, making them suitable for both residential and commercial use.

Hidden hinges, closely related to concealed hinges, are specifically designed to create a clean line when a door is closed. Unlike traditional hinges that are visible, hidden hinges can be entirely mounted within the door and frame structures. This design choice not only enhances visual beauty but also protects the hinge from environmental elements, promoting durability. Such hinges are primarily utilized in applications requiring a minimalist or sleek look, including office furniture and contemporary architecture.

Spring-loaded hinges introduce a dynamic aspect to hinge functionality. These hinges are designed with a built-in mechanism that automatically closes doors after being opened, thus promoting energy efficiency and security. They are commonly employed in commercial settings, such as in fire doors or restroom stalls, ensuring compliance with safety regulations while enhancing user convenience. The incorporation of spring-loaded hinges contributes to the practical demands of high-traffic environments where ease of use is crucial.

In essence, specialized hinges are tailored solutions for specific design needs, enhancing both aesthetic appeal and functional capability in a variety of environments. Understanding their applications allows architects, designers, and consumers to make informed choices that align with their project requirements.

Choosing the Right Hinge for Your Project

Selecting the appropriate hinge for a given project involves a thorough understanding of several essential factors. The first consideration should always be the type of material used in the hinge. Materials such as stainless steel, brass, or zinc alloy each offer unique benefits that should align with the intended use. For instance, stainless steel hinges provide excellent resistance to corrosion, making them ideal for outdoor applications or areas with high humidity, while brass hinges offer a classic aesthetic that suits traditional designs.

The weight load that the hinge will support is another critical factor in the selection process. Heavy doors or gates require robust hinges capable of bearing significant weight without compromising durability or functionality. When selecting hinges, always refer to the manufacturer’s specifications regarding weight limits to ensure suitability for your project. It is also advisable to choose multiple hinges when dealing with heavier applications to distribute the load evenly.

The installation environment plays a vital role in hinge selection. For example, if the hinge will be exposed to the elements, weather-resistant finishes should be prioritized to prevent rust and other forms of degradation. Conversely, for indoor projects, decorative hinges may take precedence, allowing for a blend of functionality and aesthetics.

Aesthetic preferences cannot be overlooked. The style of hinge must complement the overall design of the project. Options range from modern concealed hinges to more traditional exposed varieties, each contributing to the visual impact of the installation.

Lastly, proper hinge maintenance and installation are essential for maximizing both lifespan and functionality. Regular inspections should be conducted to check for signs of wear, and appropriate lubrication should be applied to hinges experiencing friction. Ensuring that hinges are installed at the correct height and level will also promote smooth operation and longevity.