Understanding Different Types of Hinges

In the realm of construction and manufacturing, hinges play a critical role, facilitating the movement of doors, gates, and various other applications. It is essential for procurement managers to have a clear understanding of the different types of hinges available on the market. This knowledge can significantly influence the measurement process, ensuring that the appropriate hinge type is selected for specific tasks. Among the various types of hinges, the most common include butt hinges, continuous hinges, and pivot hinges.

Butt hinges, typically used on doors, consist of two plates that form a pin-like mechanism. They are generally made from brass, stainless steel, or steel, providing durability and mechanical reliability. These hinges require precise measurements in order to ensure that they function properly. Continuous hinges, also known as piano hinges, extend the full length of the door or panel. Their design offers increased strength and stability and is commonly fabricated from stainless steel or aluminum, which further emphasizes the importance of understanding their dimensions for accurate installation.

Pivot hinges, on the other hand, allow for a door to pivot from a single point at the top and bottom. These are particularly useful for heavy doors and wide openings. The measurement technique for pivot hinges may differ based on the application and installation requirements. Additionally, hinges can be made from various materials, including plastic, bronze, and galvanized steel, each imparting different characteristics such as corrosion resistance or aesthetic appeal.

Understanding these differentiations in hinge types and materials is crucial for procurement managers. An appropriate selection not only ensures functionality but also promotes long-term satisfaction and performance. Hence, acquiring this foundational knowledge will enable procurement professionals to measure and select hinges more effectively, aligning their choices with the specific demands of their projects.

Essential Tools for Measuring Hinges

Accurate measuring of hinges is essential for procurement managers seeking to ensure precise fits and optimal functionality in their projects. To achieve this level of precision, several key tools should be integrated into the measuring process. Among the most important are calipers, measuring tapes, and protractors, each serving a unique purpose.

Calipers are invaluable for measuring the thickness and diameter of hinges. They come in various types, including digital, dial, and vernier calipers. Digital calipers offer the advantage of easily readable measurements and high precision, which is critical when selecting hinges to match specific installation requirements. Dial calipers, while slightly less convenient, can still provide excellent accuracy for those familiar with their use. The ability to quickly and accurately measure hinge dimensions allows procurement managers to minimize errors that could lead to costly procurement mistakes.

Measuring tapes are another essential tool, particularly for gauging longer distances between hinge placements or when assessing the scale of the door or frame where a hinge will be installed. A flexible measuring tape allows for curvilinear measurements, which might be necessary if working with non-standard or customized hinge placements. Opting for a measuring tape with clear, easy-to-read markings can streamline the measurement process and enhance overall efficiency.

Protractors are employed to measure angles, which is crucial when installing hinges at specific orientations. This tool assists in ensuring proper alignment and can significantly affect the operation of the hinge mechanism. A digital protractor simplifies angle measurement further, providing immediate readings without the need for manual calculations.

Investing in high-quality measuring tools facilitates not only accuracy but also efficiency in procurement processes. Each tool listed plays a critical role in producing precise measurements, which ultimately lead to well-fitted hinges that meet performance standards. Therefore, equipping oneself with the right tools is a fundamental step for procurement managers aiming to ensure successful hinge selection and installation.

Step-by-Step Measurement Process

Measuring a hinge accurately is essential for ensuring a proper fit and function. The following guide outlines the step-by-step measurement process, emphasizing precision and offering tips for best practices.

Begin by measuring the hinge height. This is done by placing the hinge on a flat surface. Use a ruler or a caliper, positioning it vertically alongside the hinge. Measure from the top edge to the bottom edge of the hinge plate. Ensure that the ruler is perpendicular to the hinge to avoid any inaccuracies. It is advisable to take multiple measurements and record the average to enhance reliability.

Next, proceed to measure the width of the hinge. This involves placing the hinge on its side, allowing you to measure the width of the leaf. Again, ensure that the measuring tool is aligned straight across the width. Avoid the temptation to estimate; precision is key, as even minor discrepancies can lead to complications during installation.

Following the width, measure the leaf thickness. This is critical as it affects the overall strength of the hinge. Depending on the hinge design, it might involve measuring at different points along the leaf to ensure consistency. Be aware of variations, as their presence can indicate wear and may require a different hinge type.

The final measurement to take is the distance from the hinge knuckles. This measurement is vital because it ensures that the hinge will function correctly when installed. To measure it, count the number of knuckles and note their height. It can help in aligning the hinge with the doorframe during assembly.

A common mistake during this process is neglecting to double-check each measurement. It is crucial to verify all figures before proceeding with any procurement decisions. Taking time to ensure accuracy will save time and resources in the long run.

Choosing the Right Photos to Accompany Your Hinge Measurement Guide

When it comes to crafting a comprehensive guide for procurement managers on measuring hinges, the selection of accompanying visuals plays a pivotal role in enhancing the reader’s understanding. High-quality images not only break up text but also provide visual support that is essential for effectively conveying the measurement process. Clear demonstration of each step can significantly aid users in grasping the technical aspects of hinge measurement.

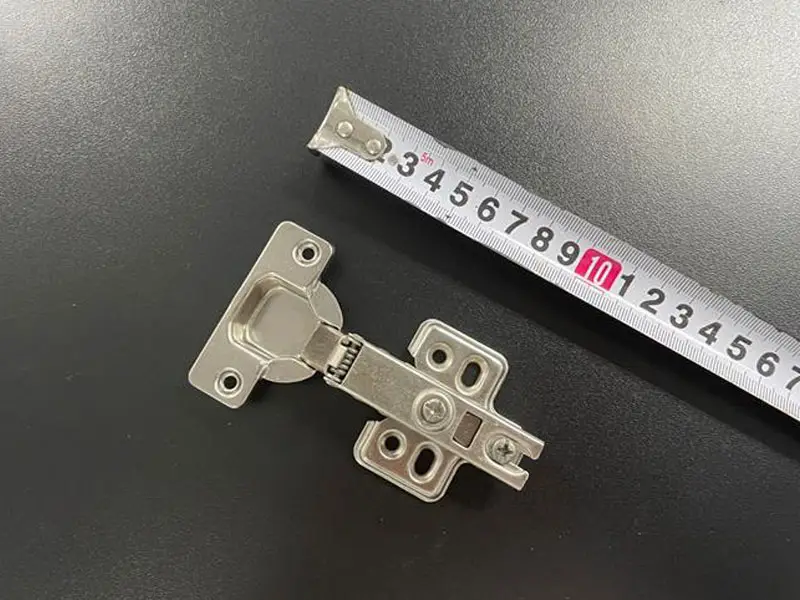

To create the most impact, focus on using images with high resolution and clarity. Photos taken in good lighting will showcase details that are crucial for accurate measurements. For example, images capturing the hinge in close-up allow the viewer to see the specifics of its design, thereby facilitating better understanding of how to measure it correctly. Utilizing multiple angles is also essential. A standard straight-on view of the hinge is beneficial, but additional shots from varying perspectives can illuminate different features that may affect the measurement process.

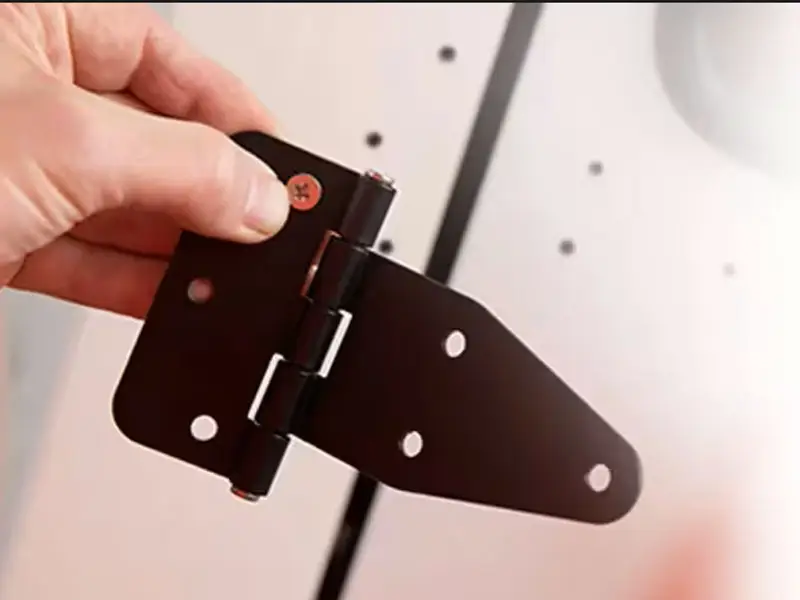

Moreover, including contextual images that display various types of hinges, such as butt hinges, continuous hinges, and pivot hinges, will broaden the scope of the guide. This diversity in visuals helps readers identify which type they are working with, ensuring the measurements taken are relevant to the specific hinge they are addressing. Also, images demonstrating the measurement tools themselves, such as calipers or tape measures, are valuable. This practice not only familiarizes readers with the appropriate instruments but also reinforces their importance in achieving accurate results.

Engaging and informative visuals can greatly enhance the reader’s experience. By integrating well-selected images into the hinge measurement guide, procurement managers will find that they are better equipped to follow the outlined steps, ultimately leading to more precise measurements and improved outcomes in their procurement activities.